Building a Table for the Ox

The DOX (Don's OX) Table Build

|

| Finally all CNC's in one place in my shop. Both laser and Router are on movable bases |

Goals:

- Strong

- Sits on the floor when in operation but can be moved easily

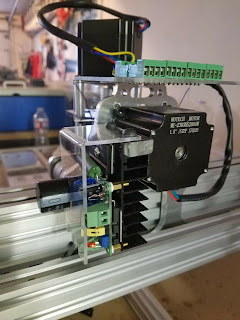

- Houses electronics

- Room for a hood added at a later time

- Space for electronics

Design:

- Materials: dimensional lumber from big box stores

- 3/4" MDF thick top

- Integrated lift: lifts entire table up on casters for movement

- Storage space

- Space for drawers, electronics, PC or tablet

General Parts

Frame parts: 2x4 and 2x6, 96" length

Cam lags: 1/2 x 6" and flat washer.

Most other hardware: 1/4 x 5" lag screws and washers

Top: 3/4 MDF, size to your liking

Shelf: 1/4" fiber board or material to your liking

|

| A rough cut-list for the V3 model below |

Initial Build Complete

|

| The table cut and kitted |

|

| 1/2 x 6" lag screws in cams |

|

| The top frame parts were plane'd flat on the joiner |

|

| Pretty Flat |

Mobility

The main feature of the table is the cam system that allows the table to be lifted 1/4-1/2 so that it can be moved in my shop or on a nice day out into the driveway.

Space for Electronics

Next!

Comments

Post a Comment