Dust Extraction 1.0

Dust Shoe and Hose Management Designs

There are many dust shoe designs both commercial and DIY for dust extraction in a CNC.

Mostly I do not like that the dust shoe seems to be in the way and it blocks the view of the bit. Perhaps as I become more confident with my CNC programming I will not care if the bit is visible.

Furthermore the vacuum hose designs I reviewed were quite complex and generally put stress on the gantry.

I set out to see if I could design/build something simpler and easier to use.

Prototype Dust Shoe

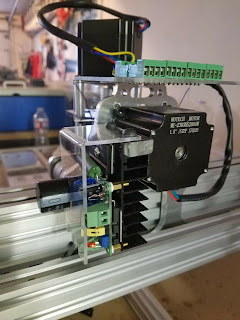

I decided to see if I could build a plenum that attached to the spindle bracket and pull air from around the bit. This would be simple to adjust up/down and simple to get on and off without obstructing the view of the bit.

I postulated that if the orifice at the bit was kept close enough and the velocity high enough I could pull away most of the chips. Alternately I could add air to try and blow the dust toward the vacuum plenum.

In the prototype below:

Plenum;

I used a section of the rung from a pvc fence as the plenum closing one end with a hunk of acrylic and the other with piece glued at a 90 long enough to reach the bit

Mounting:

The assy. is mounted to a bracket that is mounted to the spindle bracket.

The plenum has heat inserted threaded fasteners and the bracket has slots to allow up/down adjustments. Note: the plastic was replaced by a like bracket made of metal.

Hose Attachment

I found a PVC fitting that fit the face of the plenum and was a close match to the hose size. I turned the ID of the fitting to match the hose and glued the fitting to the face of the plenum.

Vacuum Hose Management

Virtually by accident during the plenum fabrication it seemed that the hose could simply be fed from the end of the machine. As the gantry moved the hose might follow?

I expected that the hose needed a rotating tube at the end of the machine to enable smooth movement so I built two brackets that loosely held a PVC pipe enabling it to rotate. Turns out that the PVC was smooth enough to allow the hose to follow the gantry an a rotating member was not needed.

|

| Rotating feed roller |

|

| Stationary Feed Roller |

TESTING

I was more than satisfied that this simple dust shoe and hose management removed most of the dust. I need to verify its operation with a higher load but for now its working fine.

Enjoy and comment;

Don

Comments

Post a Comment